-

ETHABLE-ADY-G

ETHABLE-ADY-G

(Alcohol tolerant Active dried yeast)

PRODUCT INFORMATION

- Ethable-ADY-G is a high-quality yeast strain designed for higher alcohol yield from a variety of grain based raw materials like corn, rice, wheat, sorghum, millets, cassava. This is suitable for use in production of beverage, industrial and fuel grade ethanol differentiated by faster budding, increased fermentation rate and reduced fermentation cycles, tolerance to higher alcohol concentrations and high gravity fermentation

CHARACTERISTICS:

PHYSICAL STATE GRANULAR POWDER Color Tan –pale beige Odor Mild yeasty Optimum pH 4.5 – 5.5 Optimum temperature 30-to-40-degree Celsius Dosage range 5 – 6 kg/ 100,000 liters of wash Tolerance to sugar content ≤ 15% Ethanol tolerance ≤ 16% BENEFITS:

Ethable-ADY-G has the following benefits:

- Works on various grains, cassava

- High gravity fermentation

- Rapid fermentation rate

- Higher alcohol yield

- Very low volatile production

- Tolerant to higher sugar content up to 15%

- Tolerant to higher alcohol concentration up to 16%.

- Higher temperature tolerance up to 40-degree Celsius.

- Tolerant to process deviations.

APPLICATION GUIDELINES:

- Ethable-ADY-G is suitable for use under typical fermentation conditions. Under optimum conditions of pH 4.5 – 5.5 and temperature 30 – 40 C the recommended dosage is 5 – 6 kg/ 100, 000 liter of wash or fermenter mash.

- Ethable-ADY-G has to be rehydrated in lukewarm water of about 35 – 40 C for 15 minutes. It is then acclimatized by adding this solution to pre-fermenter media for 15 minutes before mixing with the fermenter media.

PACKING

Ethable-ADY-G is available in a 10 kg foil pack.

STORAGE AND SHELF LIFE

Ethable-ADY-G should be stored in a cool and dry environment below 25 C. The product should be contained in a sealed package. This is stable for 12 months under these conditions.

-

ETHABLE-ALPHA

ETHABLE-ALPHA

(Next Generation Enzymes for Liquefaction (Grain Processing)

Description

- Alpha4 2X is an Alpha-Amylase that hydrolyses (1,4)-alpha-D-glucosidic linkages in starch substrates.

- Alpha4 2X is heat stable and efficient in viscosity reduction over wide range of pH.

- Alpha4 2X is an endo amylase derived from select strains of Bacillus sp.

APPLICATION USE

Alpha4 2X is used during the slurry preparation and liquefaction process. As per the plant condition we can decide to split the dosages in slurry and liquefaction tanks Alpha4 2X is effective in viscosity reduction and during high DS liquefaction.

The recommended parameters are to maintain the liquefaction temp 83-85 C with overall retention time of 150-180 minutes to achieve optimum results

Product specifications:Form Light brown liquid Odor Slight fermentation Solubility Miscible in water pH Range 5.0 % to 6.5% Specific gravity 1.0 to 1.2 Recommended operating parameters:

Dosage 0.40 – 0.50 KG/Per ton of starch Optimum pH 5.5 – 6.0 Optimum Temperature 83 – 85 c Retention time 150 – 180 minutes Packaging:

HDPE package contains 30kg (66lb).

Safety and Handling procedure

Storage conditions- This enzyme has been formulated for optimal stability. The recommended storage condition is 0-25 C. Container should be dry, sealed and kept away from sunlight.

Safety and Handling procedure- Enzymes may cause allergic reactions, Inhalation of dust and aerosol should be avoided. Spilled enzyme should be cleaned with plenty of water immediately. Please Read our safety manual for complete details.

-

ETHABLE-BOOST-G

ETHABLE-BOOST-G

(Grain Fermentation Booster)

Product Description:

Ethable-Boost-G is a specialized multi-enzyme blend designed to optimize grain fermentation processes by efficiently hydrolyzing starch and proteins. This enhances alcohol yield while maintaining high quality standards throughout fermentation.

Benefits:

Increases alcohol yield by maximizing starch-to-sugar conversion. Reduces microbial contamination, volatile acidity, and fermentation time. Enhances yeast propagation, strengthening yeast cell walls for improved performance. Improves efficiency in starch conversion to fermentable sugars, promoting robust fermentation dynamics. Minimizes foaming and scum formation during the fermentation process. Ensures no negative impact on alcohol quality or effluent treatment. Facilitates a consistent and predictable fermentation process. Efficiently breaks down starch into fermentable sugars, enhancing liquefaction and saccharification. Reduces mash viscosity, improving mixing dynamics and overall fermentation efficiency. Product Characteristics:

Attribute Description Composition Blend of essential enzymes and nutrients, including Protease enzymes Form Buffered powder Appearance Off-white to brownish Operating Parameters:

Parameter Range pH Range 4.0 – 5.5 Temperature Range 30 – 45°C Dose Recommendation:

3-5 ppm of the wort.

Application:

Suitable for enhancing grain fermentation processes.

-

ETHABLE-FE-G

ETHABLE-FE-G

(Urea & DAP Replacement ( Blend of Bio Nutrients and microbes ) in Grain Fermentation)

Product Description:

Ethable-FE-G (Transforming Fermentation Efficiency: The Future of Nitrogen Source Replacement)

Innovative Blend:

- Ethable-FE-G offers a distinctive blend of bio-nutrients and bio-catalysts, specifically formulated for grain-based distillery processes.

Replacement for Conventional Nitrogen Sources:

- Effectively replaces traditional nitrogen sources such as Urea, DAP, and liquor ammonia, enhancing efficiency and sustainability.

Optimizes Yeast Growth:

- Utilizes Actinomycetes and Pseudomonas (some strain) cultures for ammonia synthesis and Bacillus cultures for enzymatic hydrolysis, promoting robust yeast growth.

Accelerates Fermentation:

- Significantly boosts fermentation rates and yield potentials through optimized metabolic processes tailored for grain-based substrates.

Versatile Integration:

- Ideal for yeast propagation, pre-fermentation, and fermentation stages, with adaptable dosage options to suit various production requirements.

Liquid Formulation:

- Presented as a light brown liquid with an optimized pH range, maintaining scientific precision and operational efficiency.

Comprehensive Nutrient Support:

- Supplies essential nutrients such as phosphorus, potassium, zinc, manganese, and sulfur, crucial for yeast vitality and robust fermentation.

Elevates Distillery Operations:

- Combines scientific innovation with operational excellence, enhancing precision, profitability, and fermentation efficiency in grain-based distilleries.

Applications:

- Grain-based Distillery Fermentation

Product Features:

- Encompasses bio-nutrients, proprietary cultures, and biocatalysts.

- Enhances fermentation processes specific to grain-based feedstocks.

- Promotes sustainable environmental practices.

Benefits:

- Improves overall system performance and productivity.

- Reduces operational costs by optimizing treatment efficiency.

- Minimizes sludge volume and associated handling costs.

- Reduces unpleasant Odors associated with fermentation.

Objective-

- Yeast re-pitching

- High gravity sugar Fermentation

- High stress Fermentations environment

- Improves attenuation and speed of fermentation

Dosage and Usage:

- Recommended Dosage: customised based on plants need (1/15 of Urea+DAP used)

- Optimal pH Range: 3.5 to 5.1.

- Operating Temperature Range: 25-50°C.

Physical Properties:

- Appearance: Liquid.

- Color: Light Brown.

- Odor: Fermentation Odor.

- Specific Gravity: 1.006 to 1.040.

- Shelf Life: 18 Months

Storage Instructions:

- Store in a cool, dry place to maintain product stability.

- Keep the container tightly sealed to prevent contamination.

- Avoid exposure to extreme temperatures for optimal efficacy.

Health and Safety:

- Environmentally friendly and biodegradable formulation.

- Non-toxic and safe for routine handling.

- Use appropriate personal protective equipment (PPE) during handling.

- Avoid direct contact with skin and eyes; rinse thoroughly with water if contact occurs.

Resilient Packaging:

- Packaged in durable 25L HDPE vessels to ensure product integrity and long-lasting efficacy.

Technical Support:

- Comprehensive technical support and expert guidance available to ensure optimal usage and results.

-

ETHABLE-GLUCO

ETHABLE-GLUCO

(Next Generation Enzymes for saccharification (Grain Processing)

Description

- In the production of alcohol and spirits from grain, the saccharification enzymes degrade gelatinized starch and dextrin into fermentable sugars. These sugars are then converted or fermented by the yeast cells into alcohol.

- Ethable Inc. has developed a range of saccharification products in order to enhance starch processing in grain-based distilleries. Ethable Inc’s saccharification product, Ethable-Gluco, consists exo-1, 4-alpha-D-glucosidases (glucoamylases) obtained from Aspergillus Niger.

GLUCO6 2X CHARACTERISTICS

- pH Range: 3.5 – 4.5

- Temperature Range: 30-75 °C

- Dosage Range: 0.50 – 0.60 kg/MT Starch

- Activity: 3000-3500 Unit/g

ADVANTAGES OVER OTHER ENZYMES

For the production of Alcohol from grain substrates, Ethable-Gluco provides the following benefits:

- Works over broader pH and temperature range.

- More Efficient degradation of dextrin.

- Reduced risk of infection because of working at lower temperatures.

- Lower treatment costs and dosages

- High concentration delivers savings in logistics

- Faster Fermentation time

- Lower By product Formation

- Enhanced Alcohol Recovery

- Lower Solids in Thin Stillage

USES

For optimum results, add Ethable-Gluco just after liquefaction to the pre-tank or saccharification tank when the temperature has cooled to 65 °C.

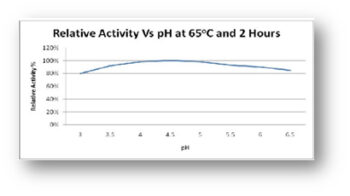

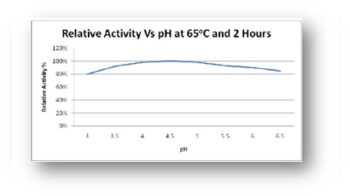

PERFORMANCE

APPLICATION GUIDELINES

Ethable-Gluco can be used in pre-saccharification or in the simultaneous saccharification and fermentation process (SSF) at a dosage of 0.40 – 0.60 kg / MT of starch based on the substrate used.

Packaging:

HDPE package contains 30kg (66lb).

STORAGE

Ideal storage conditions are 0-25 °C (32-77 °F) in sealed packaging in a dry environment protected from the sun. The products have been manufactured for optimum stability. However, enzymes gradually lose activity over time. Extended storage and/or adverse conditions such as higher temperatures or increased humidity may lead to a higher dosage requirement. Other handling instructions are available in the Material Safety Data Sheet.

SHELF LIFE

Ethable-Gluco is stable under recommended storage conditions for a period of 3 months with less than 5% drop-in activity. Drop-in activity can be compensated

SAFETY & ENZYME HANDLING

Ethable-Gluco is nontoxic, nonhazardous and non-corrosive. Inhalation of enzyme liquid should be avoided. In case of contact with the skin or eyes, promptly rinse with water for at least 15 minutes

-

ETHABLE-VMC

ETHABLE-VMC

(Antimicrobial is a dry formulation of certain antimicrobial strains along with dextrose, protease and starch (glucose) hydrolyzing enzymes)

Description:

Ethable-VMC, antimicrobial is a dry formulation of certain antimicrobial strains along with dextrose, protease and starch (glucose) hydrolyzing enzymes, which are soluble in ethanol and dispersible in water, specific for use in molasses & grain-based ethanol production

Properties:

Ethable-VMC is effective during emergency and regular maintenance conditions to control Grampositive bacterial infections, because of its superior stability at low pH and high temperature during fuel ethanol fermentation. It is much more stable at mash pH levels, as low as 3.0, in contrast to other antibiotics that start degrading rapidly at pH of 5.0. As a result of its stability Ethable-VMC is effective throughout the entire fermentation process. The degradation of Ethable-VMC is ultimately a function of time and temperature. DDGS dryers typically operate at temperatures as high as 800 ⁰F and will cause rapid breakdown of antimicrobial strains.

Lactic acid is an undesirable by-product of alcohol fermentation and can stop or seriously inhibit the metabolism of carbohydrates into alcohol by yeast. Lactic acid bacteria (such as Lactobacillus sp.) are the most common type of Gram-positive bacteria that produce lactic acid, consume sugar otherwise available for ethanol production and produce enzymes that affect the fermentation process.

How does Ethable-VMC Work:

Ethable-VMC kills and stops the multiplication of Gram-positive organisms like Lactobacillus.

During alcohol fermentation, these organisms produce lactic acid. Specifically, Ethable-VMC has a natural distribution of 2 molecules (M & S factors) that inhibit protein synthesis at two different ribosomal subunit locations in the bacterial cell, which prevents bacterial cells from multiplying (bacteriostasis) or to lyse (bacterial death-bactericidal).

Dosage

Ethable-VMC is added to fermenter during fermentation. Normal recommended dosage rates are between 1 ppm to 4 ppm (2 ppm is most common) dependent upon the level of bacteria present. Concentration is calculated using the ratio of 1 ppm equals 1 lb. in 108,000 gallons. Dosage should not exceed 4.0 ppm during the fermentation cycle. STORAGE

Boxes should be stored in a cool dry space. Product should be used within two years of its production date for best performance. Packages which have lost their vacuum seal should not be used. Opened packages can be stored cool and used within 3 to 4 days..

Packaging

100 Gram pouches into 20 kg drums or customized as per customer’s requirement.

Shelf Life

This product has a shelf life of 2 years from the date of packaging and must be stored in a dry location.

-

FALI-G

FALI-G

(Fali Bioethanol Yeast (Grain) is an active dried yeast well-suited for use in simultaneous saccharification fermentations of starch substrates. It has a high tolerance to liberated glucose.)

Description

Fali Bioethanol Yeast (Grain) is an active dried yeast well-suited for use in simultaneous saccharification fermentations of starch substrates. It has a high tolerance to liberated glucose.

- Has a high cell count (> 20 x 109 cells/g)

- Rehydrates well in direct pitch applications

- Has high ethanol and temperature tolerance

- Has organic acid tolerance

- Can be used in conjunction with glucoamylase and alpha amylase enzyme systems

APPLICATION USE

This yeast product has optimal performance within a pH range of 4.0 to 5.0 but can ferment well in the range of 3.5 to 6.0. Optimal fermentation temperature is dependent on other stresses present (organic acid, ethanol and pH) but generally ferments well in the range of 32°C to 37°C (90°F to 98°F). Under proper conditions, Fali can produce ethanol up to and beyond 16% w/v.

DIRECTIONS FOR USE

- Yeast can be added directly to a fermenter at a dose rate of between 0.1 and 0.5 kilograms per 1000 liters (1 and 4 pounds per 1000 gallons).

- Yeast conditioning can also be performed to acclimate the yeast for fermentation, increase the pitching cell mass and shorten the lag phase in the fermenter.

PACKAGING

Fali Bioethanol Yeast (Grain) is packaged in vacuum-sealed foil bags and shipped in cardboard boxes. Each package contains 10kg (22lb) with 60 boxes per pallet.

STORAGE

Boxes should be stored in a cool dry space. Product should be used within two years of its production date for best performance. Packages which have lost their vacuum seal should not be used. Opened packages can be stored cool and used within 3 to 4 days..

REGULATORY

All yeast conforms to current local regulations.